The behavior of materials under stress plays a crucial role in various engineering and structural applications. Ductile and brittle fractures represent two contrasting modes of fracture, each characterized by distinct properties and responses to applied forces. Understanding the differences between ductile and brittle fractures is essential in fields such as material science, metallurgy, and structural engineering.]

Ductile Fracture:

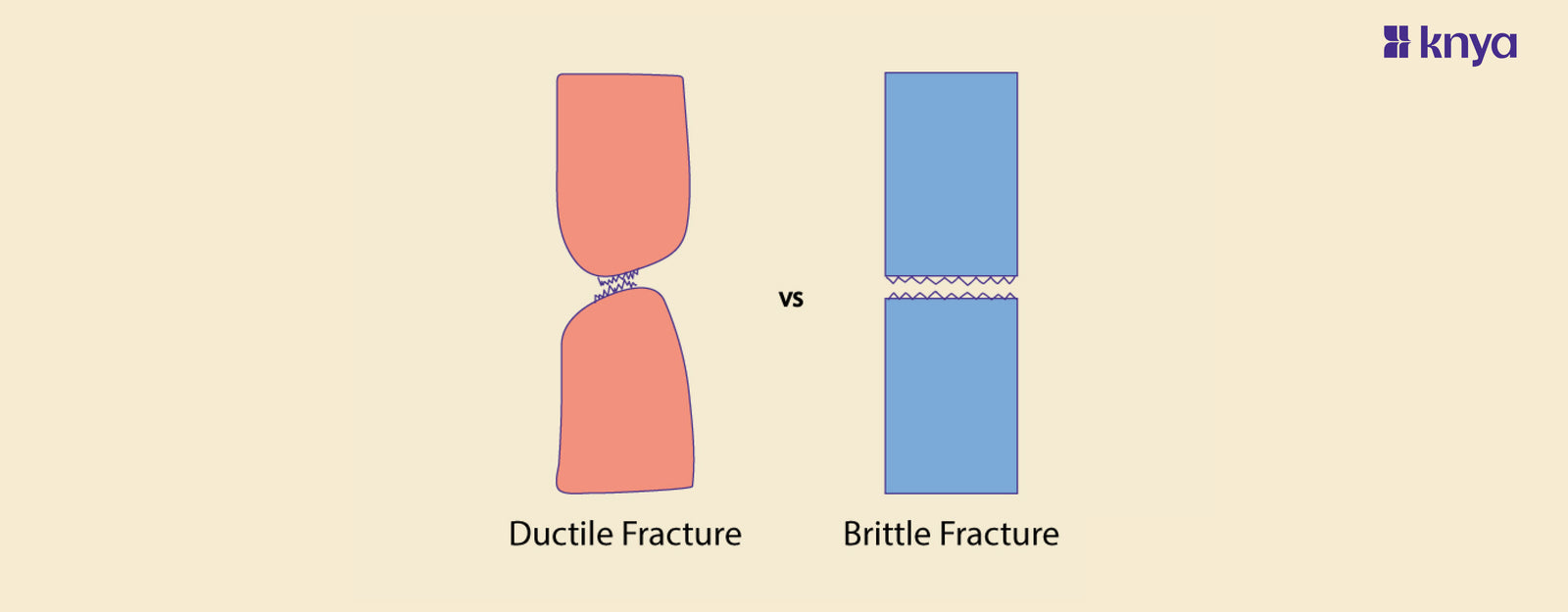

- Deformation: Ductile materials are capable of substantial plastic deformation before fracture.

- Energy Absorption: Exhibits high energy absorption capacity, allowing materials to deform extensively before ultimate failure.

- Appearance: Results in a rough and fibrous fracture surface, often displaying necking and stretching.

- Materials: Common in materials like metals and some polymers that can undergo significant plastic deformation.

Brittle Fracture:

- Deformation: Brittle materials lack significant plastic deformation capabilities and tend to fail abruptly.

- Energy Absorption: Demonstrates low energy absorption capacity, with little to no plastic deformation before failure.

- Appearance: Produces a flat, shiny, and relatively smooth fracture surface without significant deformation features.

- Materials: Characteristic of materials like ceramics, certain polymers, and some metals at low temperatures.

Difference Between Ductile and Brittle Fracture

|

Feature |

Ductile Fracture |

Brittle Fracture |

|

Deformation |

Substantial plastic deformation before fracture. |

Little to no plastic deformation; fractures abruptly. |

|

Energy Absorption |

High energy absorption capacity. |

Low energy absorption capacity. |

|

Mechanism |

Necking and stretching of the material. |

Abrupt failure without significant deformation. |

|

Fracture Surface |

Rough and fibrous appearance. |

Flat, shiny, and relatively smooth surface. |

|

Warning Signs |

Often shows signs like necking, dimpling, or localized thinning before fracture. |

Usually lacks warning signs; failure occurs without significant deformation. |

|

Microscopic Features |

Microvoid coalescence, shear band formation. |

Cleavage planes, lack of plastic deformation features. |

|

Temperature Sensitivity |

Ductility increases with temperature. |

Brittle materials often exhibit increased ductility at higher temperatures. |

|

Materials |

Common in metals, certain polymers, and some alloys. |

Common in ceramics, some polymers, and certain metals at low temperatures. |

|

Applications |

Preferred in applications requiring toughness and deformation capacity. |

Avoided in applications where sudden and catastrophic failure is undesirable. |

Check out Scrubs for Doctors Here!

What is a Ductile Fracture?

A ductile fracture is a type of material failure characterized by significant plastic deformation before ultimate rupture. Ductility refers to a material's ability to undergo substantial plastic deformation, such as stretching or necking, before breaking. Ductile fractures are typically associated with materials that can absorb a considerable amount of energy through plastic deformation.

Key Poniters on Ductile Fracture:

- Deformation: Ductile materials can undergo noticeable plastic deformation without breaking.

- Energy Absorption: These materials have a high energy absorption capacity, allowing them to deform extensively before failure.

- Appearance: Ductile fractures often result in a rough and fibrous appearance on the fracture surface.

- Warning Signs: There may be visible signs, such as necking or localized thinning, before the actual fracture occurs.

- Materials: Common examples of ductile materials include many metals, certain polymers, and some alloys.

Ductile fractures are desirable in many engineering applications because they provide warning signs and allow for deformation before complete failure, contributing to the overall safety and reliability of structures and components.

What is a Brittle Fracture?

A brittle fracture is a type of material failure characterized by little to no plastic deformation before rupture. Unlike ductile fractures, brittle fractures occur abruptly and without significant warning, often with minimal deformation of the material. Brittle materials typically have low ductility and low energy absorption capacity, leading to sudden and catastrophic failure.

Key Pointers on Brittle Fracture:

- Deformation: Brittle materials lack significant plastic deformation capabilities and tend to fail abruptly.

- Energy Absorption: They have low energy absorption capacity, resulting in little deformation before failure.

- Appearance: Brittle fractures often produce a flat, shiny, and relatively smooth fracture surface without significant signs of plastic deformation.

- Warning Signs: There is usually a lack of warning signs, such as necking or stretching, before fracture.

- Materials: Common examples of brittle materials include ceramics, some polymers, and certain metals at low temperatures.

Brittle fractures can be less desirable in certain engineering applications, especially where sudden and unpredictable failure is a concern. Understanding the brittleness or ductility of materials is crucial for designing structures and components to withstand applied loads and environmental conditions.

Get the Perfect Lab Coats for your Medical Attire here!

Similarity Between Ductile and Brittle Fractures

While ductile and brittle fractures represent contrasting modes of material failure, there is a fundamental similarity they both involve the separation of material into two or more pieces. Beyond this commonality, some similarities can be identified:

- Fracture Initiation: In both ductile and brittle fractures, the process often begins with the initiation of a crack or a flaw in the material. The subsequent propagation of the crack leads to the eventual separation of the material.

- Material Failure: Both types of fractures result in the loss of structural integrity, rendering the material unable to perform its intended function. The manner and characteristics of the fracture, however, differ significantly.

- Impact on Structural Stability: Ductile and brittle fractures can compromise the structural stability of components and structures. Understanding the fracture behavior is crucial in designing materials and structures to withstand applied loads.

- Influence on Safety: Whether a material exhibits ductile or brittle behavior, both types of fractures have implications for safety considerations in engineering and design. Engineers must account for the fracture characteristics when assessing the reliability and integrity of structures.

While these similarities exist, it's important to note that the crucial distinctions lie in the mechanisms leading to fracture, the extent of plastic deformation, and the warning signs (or lack thereof) before failure in ductile and brittle fractures.